Developing future-proof solutions

Whether complex systems or small detailed solutions, we are happy to develop new components for you or derive suitable variants from our existing products. Our engineers will work closely with you to find the optimum solution for your production or products.

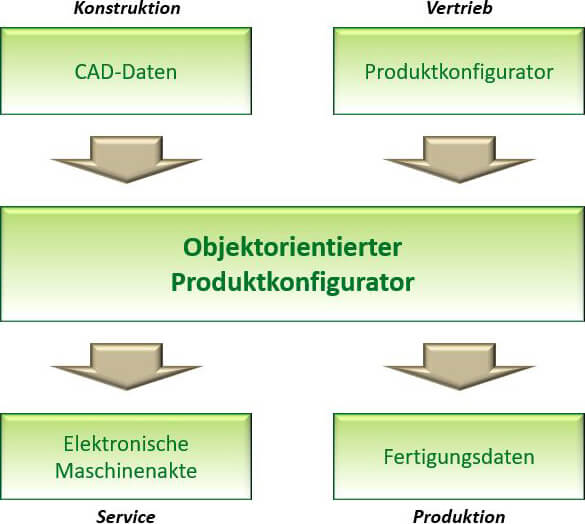

Hardware Engineering

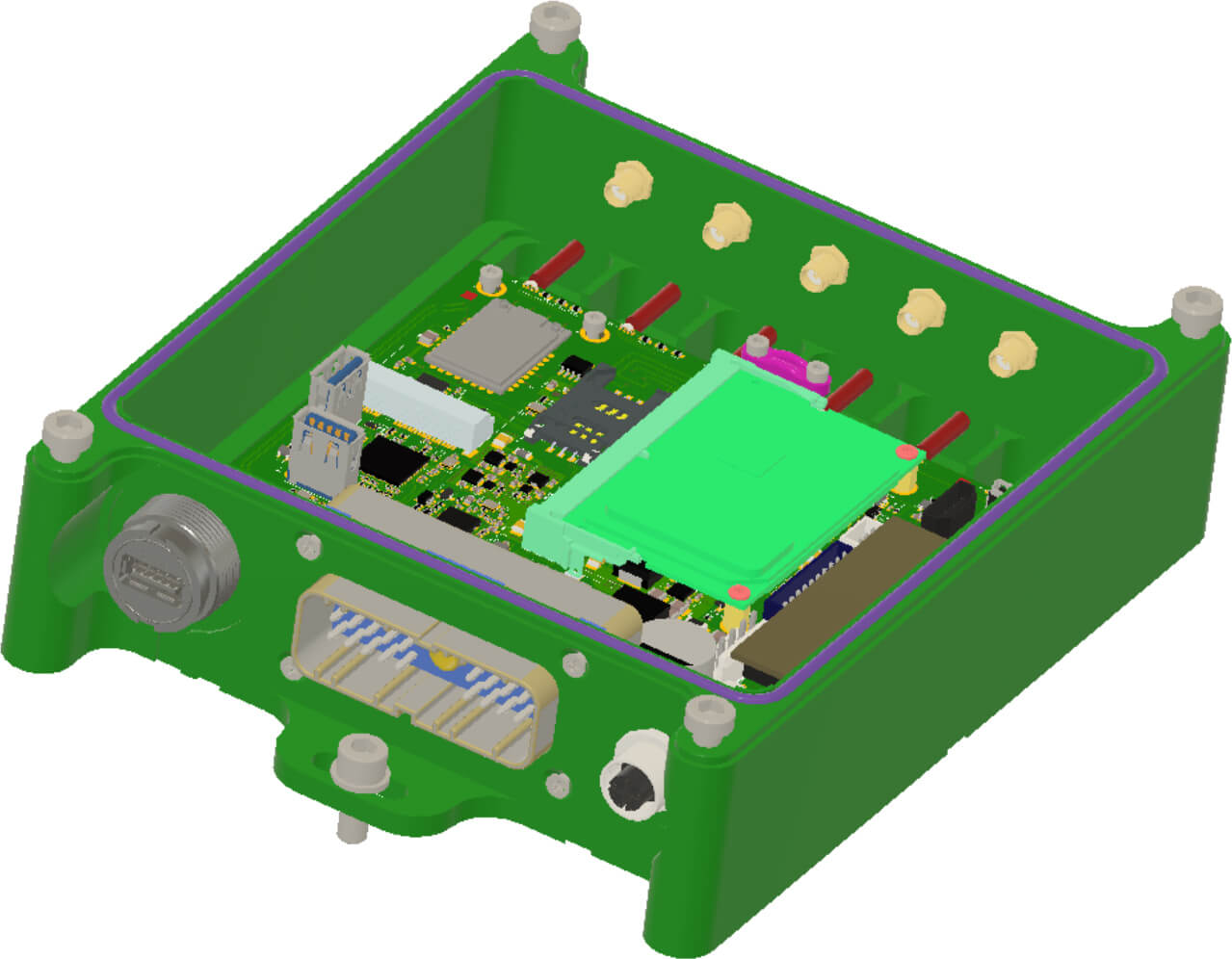

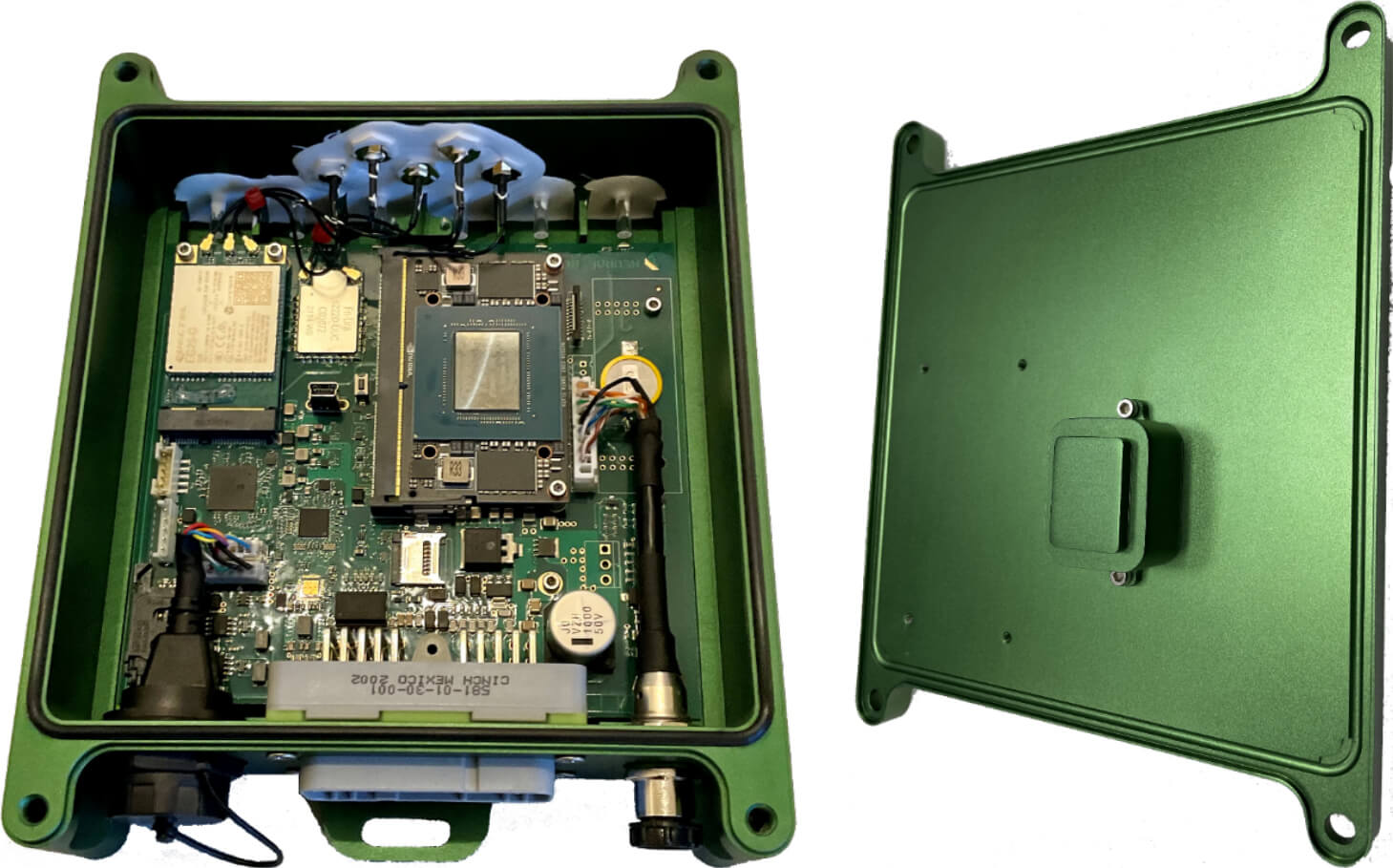

With our modern 3D toolchain, we develop electronic circuits, layout the circuit boards and embed them in suitable housing systems, whether for the control cabinet or for direct use on the machine in harsh environments. Our development team offers many years of experience in the design of control components and sensor systems.

Software Engineering

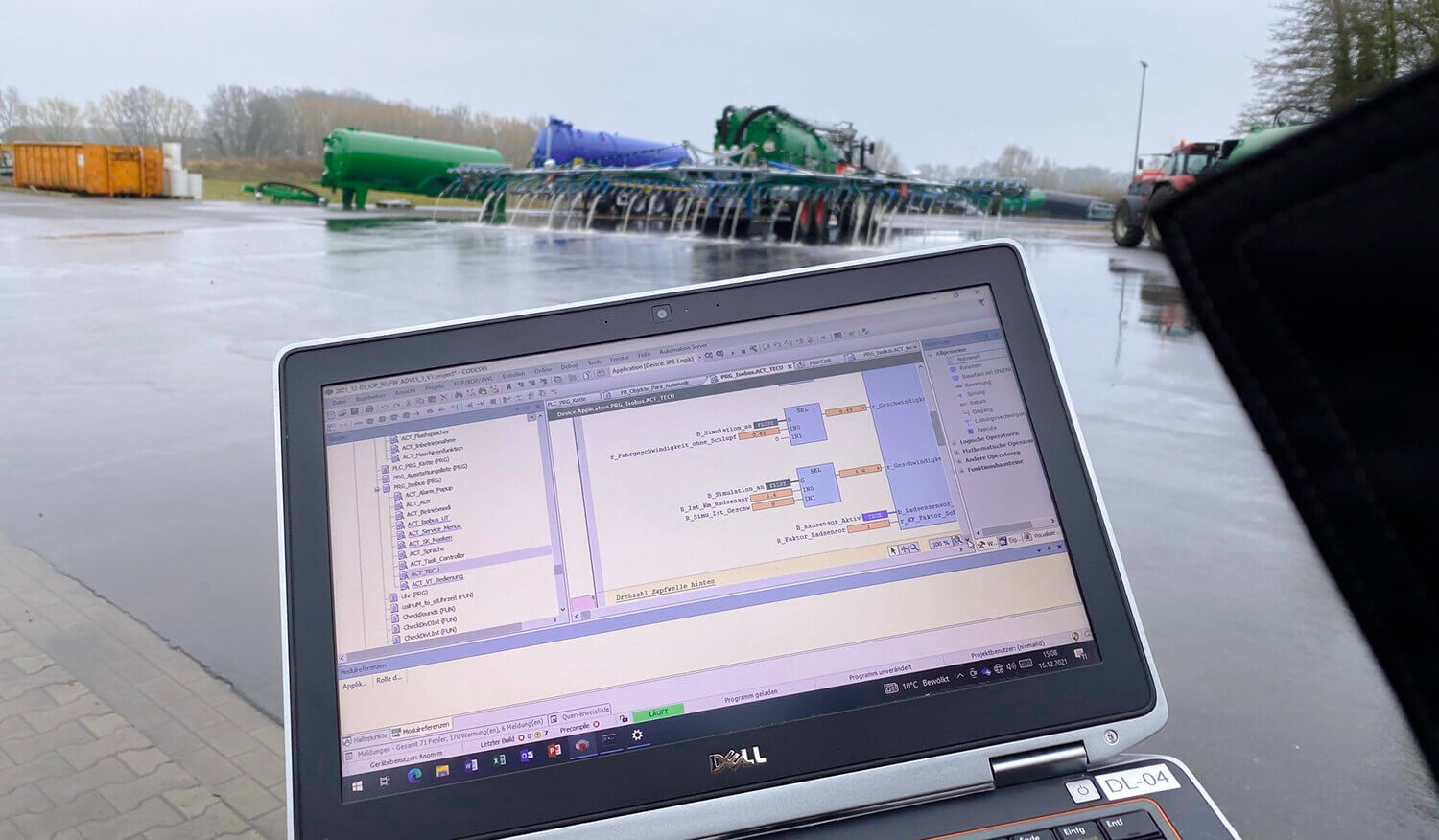

From hardware-related firmware to complex applications, in combination with databases and cloud connections, we develop your optimal solution. Together with ISOBUS, embedding Machine Learning / AI into control systems with conventional (PLC) programming is one of our core competencies.

Electrical engineering

Together with you, we design a flexible and future-oriented machine control system with an optimal hydraulic and electrical engineering. We make the data usable for customer-specific circuit diagrams, automated creation of cable harnesses, the digital twin and intelligent product configurators.

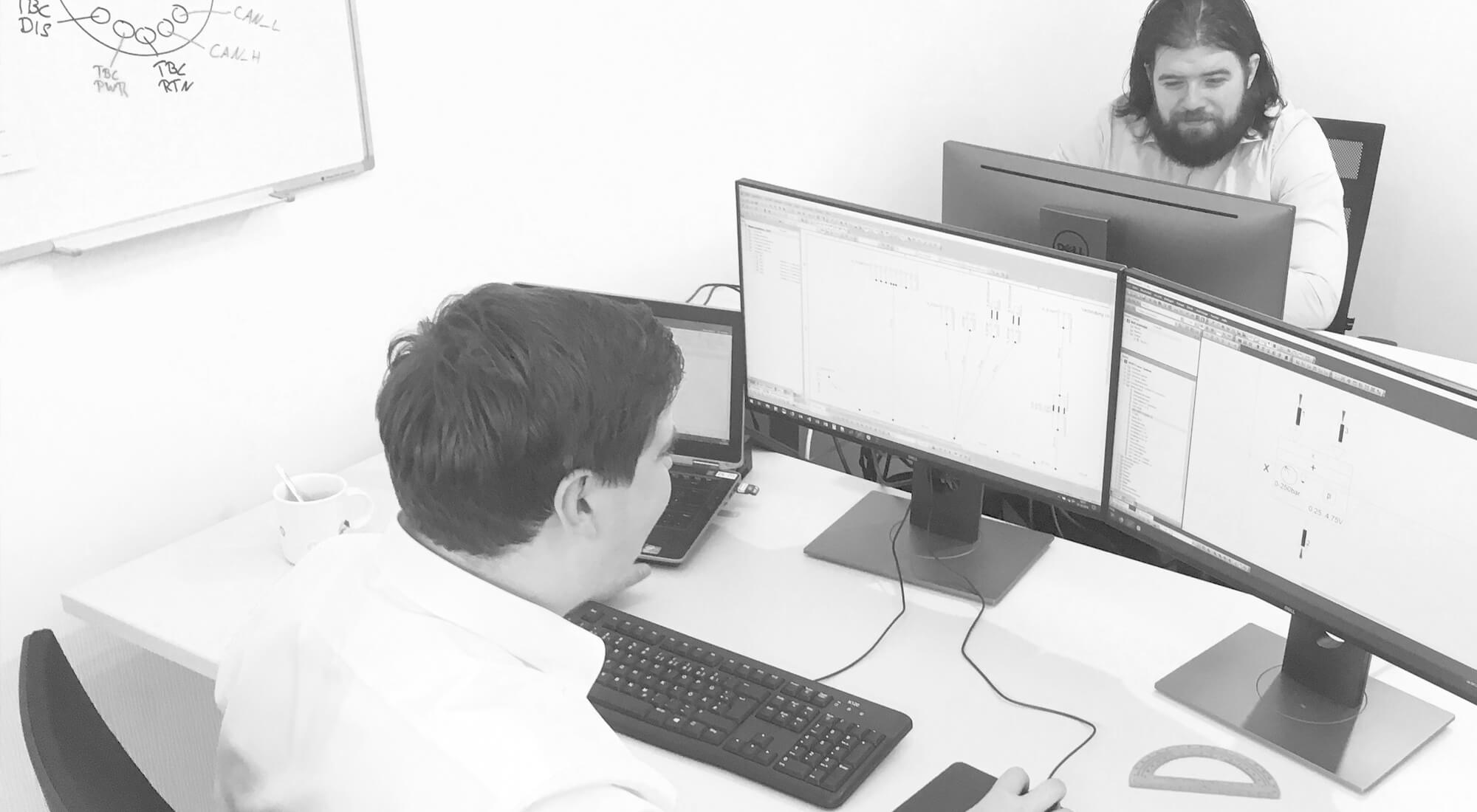

Control architecture

Are you looking for holistic system consulting for a new development or do you want to revise an existing machine control system? With our many years of expertise, we find the most efficient solutions together. Together with you, we design a modular architecture across all machine types that spans the entire product life cycle. From the most suitable sensor to the control unit to the actuator, we find optimal solutions. We always focus on reliability and cost efficiency.

Smart circuit diagrams

We plan the design of a flexible and future-oriented machine control system together with you and develop an optimal electrical system for your machine using the modern CAD tool Zuken E³. We offer practical solutions for a consistent, combined electrical and pneumatic / hydraulic concept with matching design and documentation. Electronic, electrical and hydraulic / pneumatic components can be optimally linked in the circuit diagrams to create high-quality documentation with smart linking for your machines.

Digital twin

From a master circuit diagram with electrical and pneumatic/hydraulic components for a machine series, all documents for the individual production and service of each machine built to customer specifications can be derived and then archived. Subsequent changes to individual machines can also be tracked accordingly.

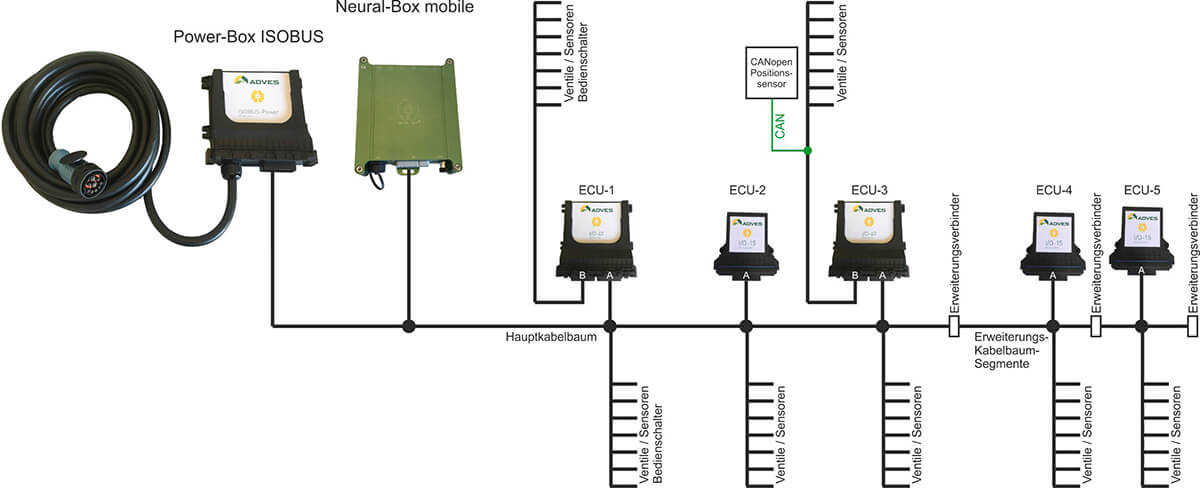

Object Oriented Product configurators

Machines are becoming increasingly sophisticated and complex, which is why series machines are optimally configured and individually manufactured for the operating conditions, the size of the operation, the logistics requirement and the type of use. The large number of different configurations results in a high degree of complexity and variance in the equipment options, and no two machines are alike in terms of production. With the help of the CAD data of the electrical design and from the configuration data of the sales department, exported from ERP systems, an object-oriented product configurator for production can generate customer-specific manufacturing data with machine-specific circuit diagrams and BOMs.

For service, the object-oriented product configurator generates an individual electronic machine file in the sense of a digital twin, which contains all customer- and machine-specific data for every single machine. This means that service work can be carried out both comprehensively and individually at any time.

Cabling systems

Production documents and digital data for the assembly of cable harnesses and cable harnesses can be derived directly from our smart circuit diagrams for the manufacturers. With appropriately adapted scripts, we generate parts lists for the assembly material, data for the cutting and printing machines, wiring and nail board plans.

IEC 61131 - CODESYS

ISOBUS

Your ISOBUS development from the idea to certification: If you want to keep pace with the latest developments for the benefit of your customers, you need competent partners. Our engineering team knows the ISOBUS in all its complexity. Benefit from our comprehensive know-how and avoid the numerous pitfalls in the development phase. We support your ISOBUS applications throughout the entire life cycle. From the idea to certification and beyond, we are at your side with our many years of experience. Ensure maximum compatibility of your products in the ISOBUS landscape and give your customers access to the latest trends and technologies.

We support you on the way to the AEF certificate: The certificate is your machine’s entry ticket to the AEF compatibility database. You put your customer in a position to check the extensive ISOBUS compatibility of their machine with their own eyes. Encourage your customers to feel that they are making the right investment with your machines.

User interface concepts with ISOBUS, Target and Web Visualisation

In addition to visualisation via the ISOBUS, there is an increasing demand for solutions to visualise machine data via web services directly on the machine on mobile devices for on-site service or via the mobile internet as remote service. We offer you consistent operating concepts, consistent for ISOBUS terminals or any web browser.

Structured / Object Oriented Programming

From programming hardware-related drivers to firmware and middleware applications to complex applications, our experienced engineering team is skilled in the languages of structured and object-oriented programming, such as C and C++. Particularly in the field of AI and data science, Python has established itself as the leading programming and scripting language, and we are happy to support you with our expertise here as well.

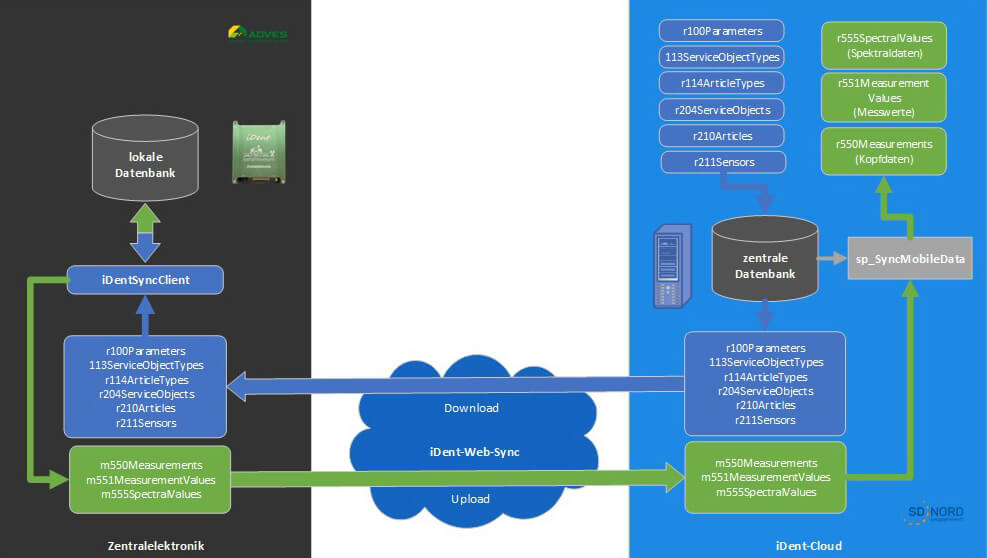

Databases / Cloud

Data is, as we all know, the “gold of the future”. This trend is of course also boosted by the application of AI methods and data science, which require a corresponding amount of data as a basis. However, it is the usability and discoverability of this data that is the key to value. It is therefore important that the data from the machines and processes are stored in a structured way in adequate databases. From our experience, concepts of synchronised local edge databases with central cloud-based databases have proven successful. We have successfully implemented these concepts in many projects.

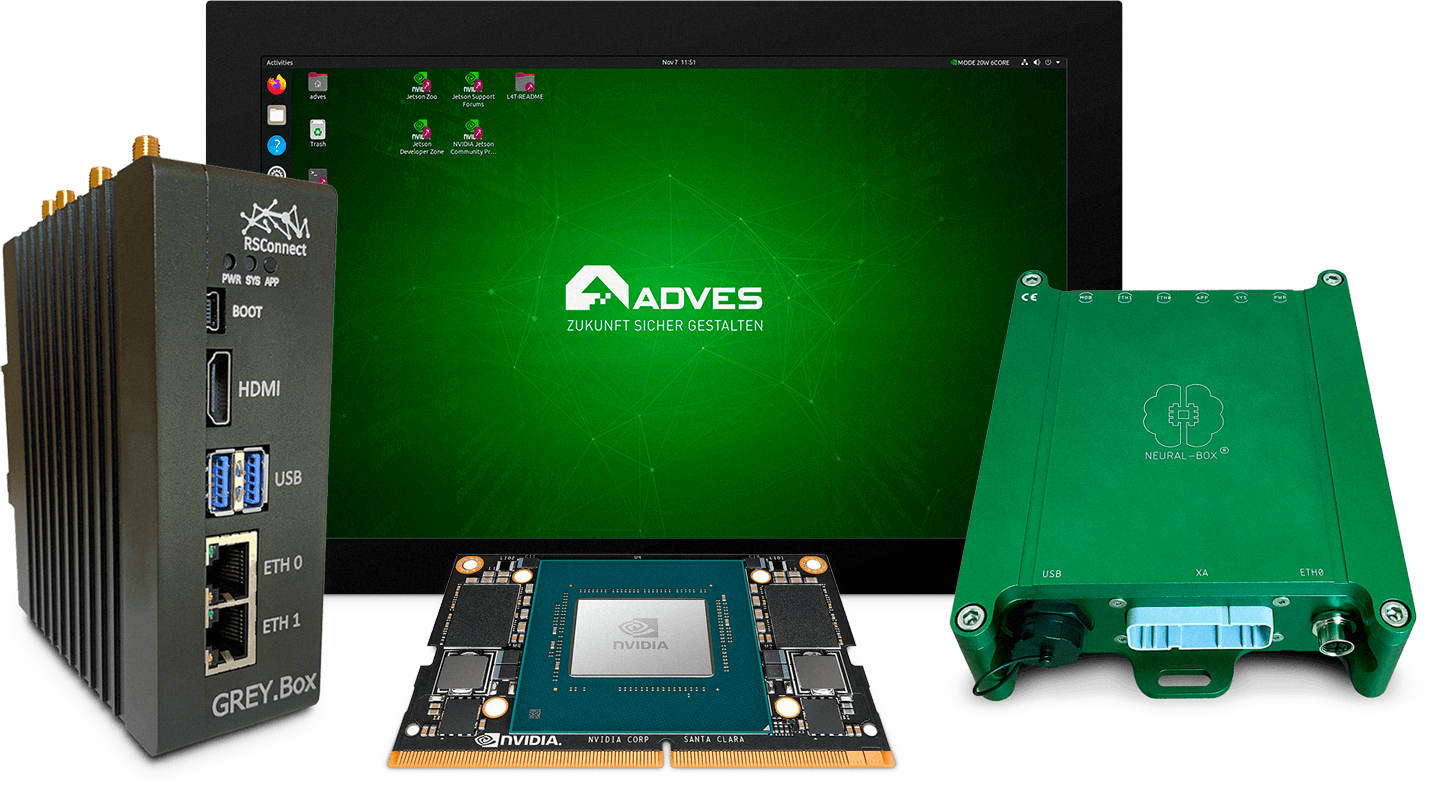

Artificial Intelligence (AI)

More training instead of programming: The world of automation has become much more analogue and the algorithms in control programming far more complex to meet all the requirements of modern production processes. This is where the potential lies for the integration of AI methods embedded in the mobile and PLC controls, especially when it comes to the evaluation and classification of sensor-based scenarios, which are easier to train in an AI framework than to program out in the last detail in a conventional algorithmic way.

In all devices of our Neural-Box ® family, even complex AI methods can be easily embedded into conventional IEC61131 programming in real time due to the integrated AI acceleration.

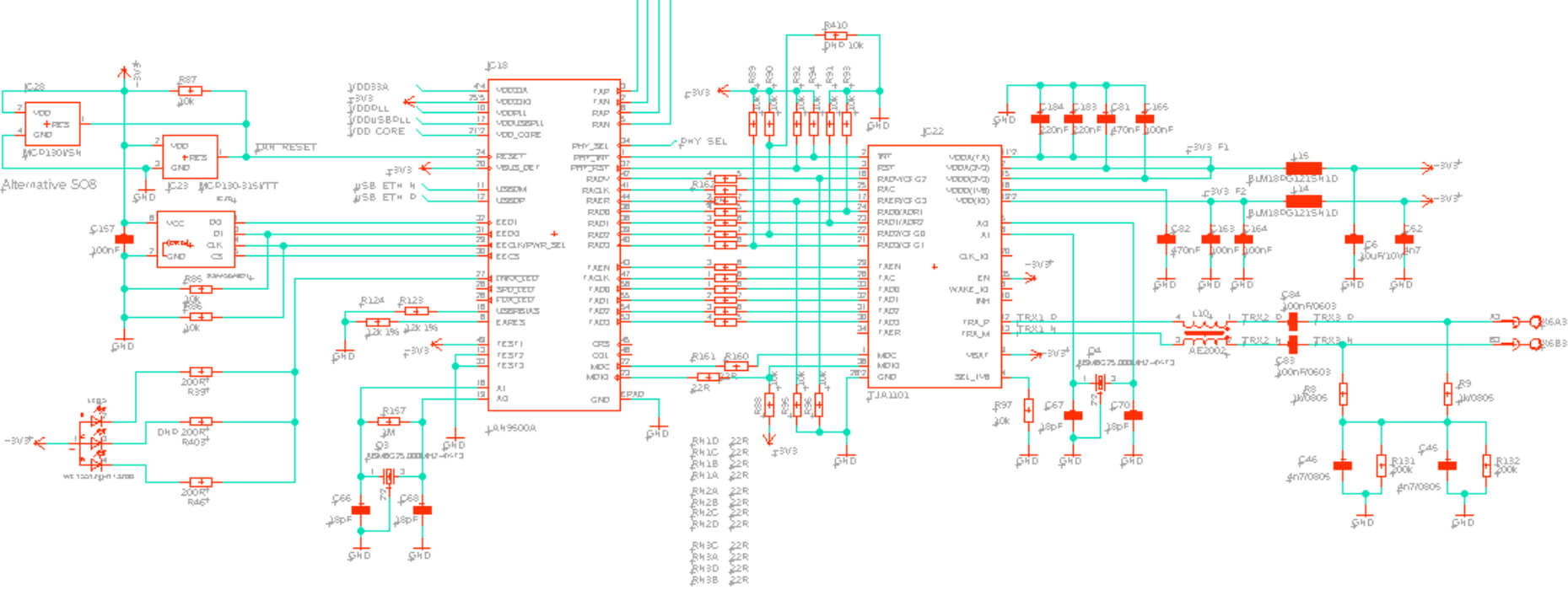

Circuit design

Circuit concepts are subject to rapid change; we routinely integrate even the most powerful interfaces and state-of-the-art components into your designs, in every available technology. Right from the start of the circuit design, we focus on the design for harsh operating conditions, high interference immunity and minimum interference emission.

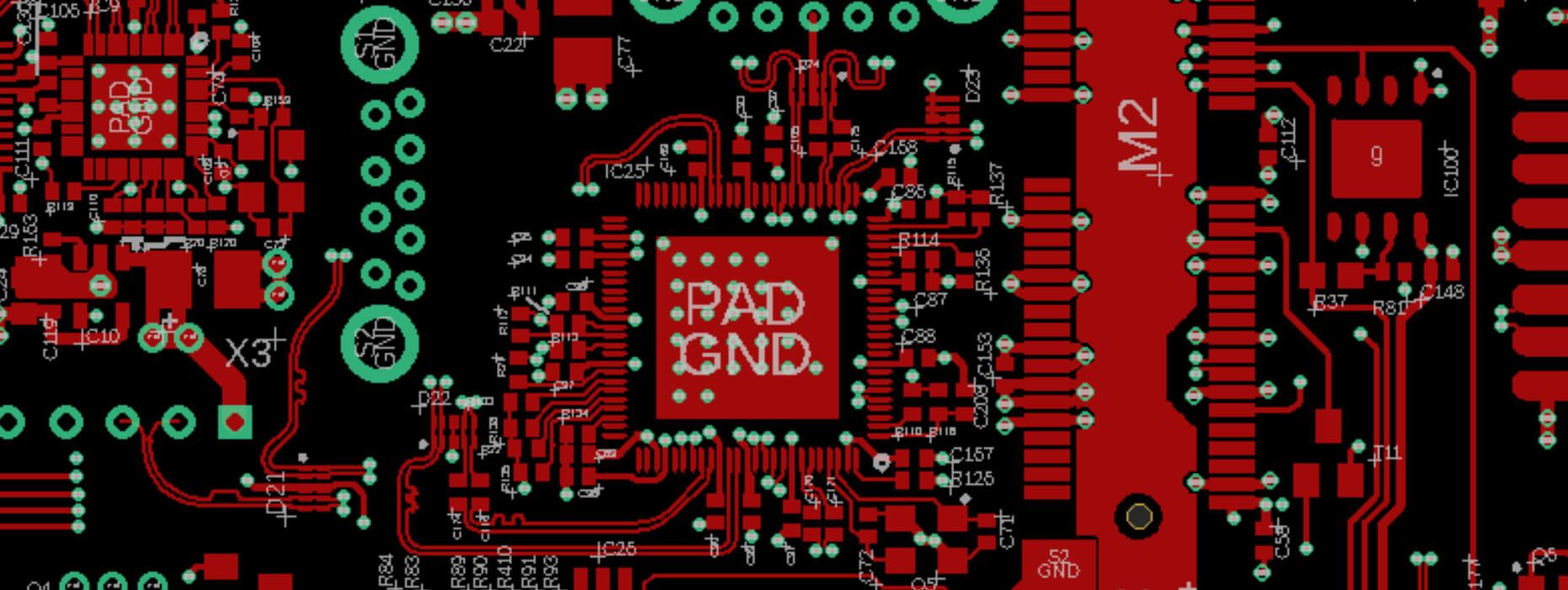

Layout and routing of the circuit board

Modern high-speed interfaces communicate at up to more than 10 gigabits per second, with very special requirements for the material of the PCB, the layer structure and the routing of the conductors. These sophisticated high-frequency designs are in good hands with our experienced engineering team.

Generation of the production data for the assembly

High-performance circuits require careful selection and detailed specification of the selected components. In times of highly volatile markets, you benefit from our experience in the procurement and selection of possible replacement components. Together with our EMS service providers, we ensure that your assembly permanently meets the high quality targets even in the production run, regardless of quantities.

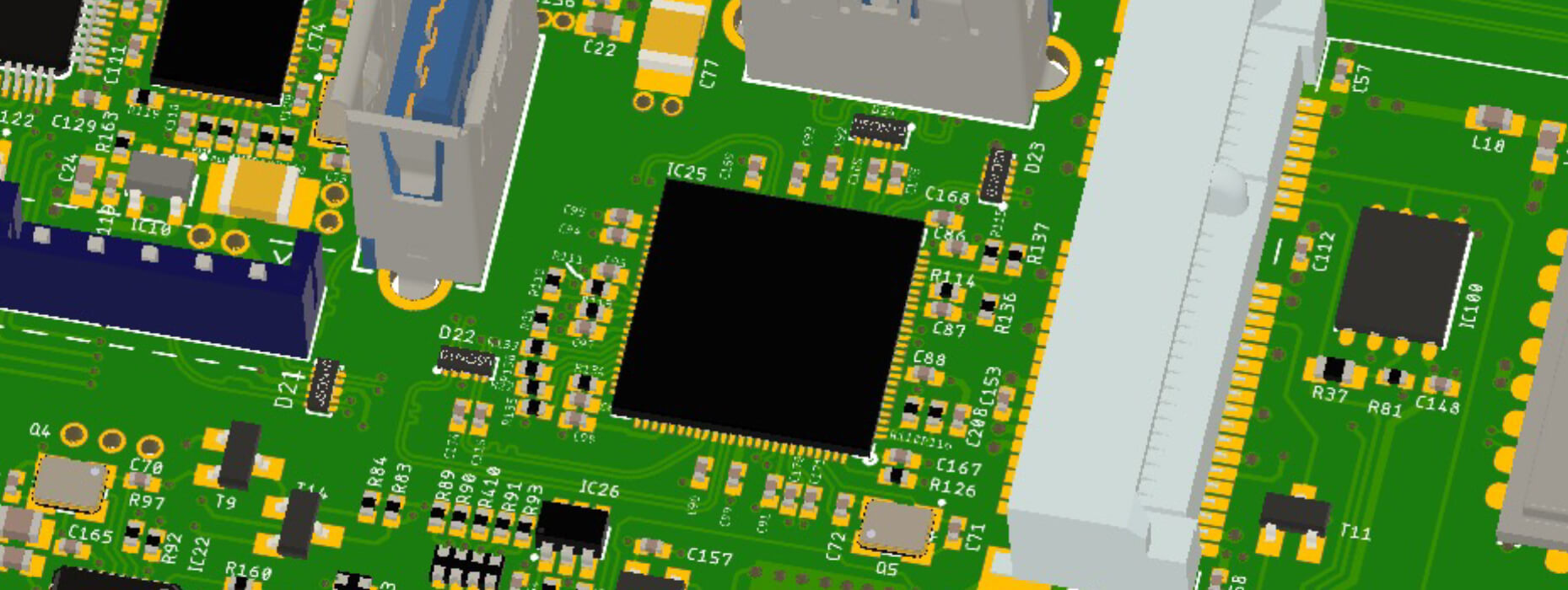

Assembled PCB – Commissioning

Complex circuits and design drafts are transferred to the prototype stage in a very short time, and by using the latest soldering and measurement technology, even sophisticated circuits can be built and evaluated for practical use in a very short time.

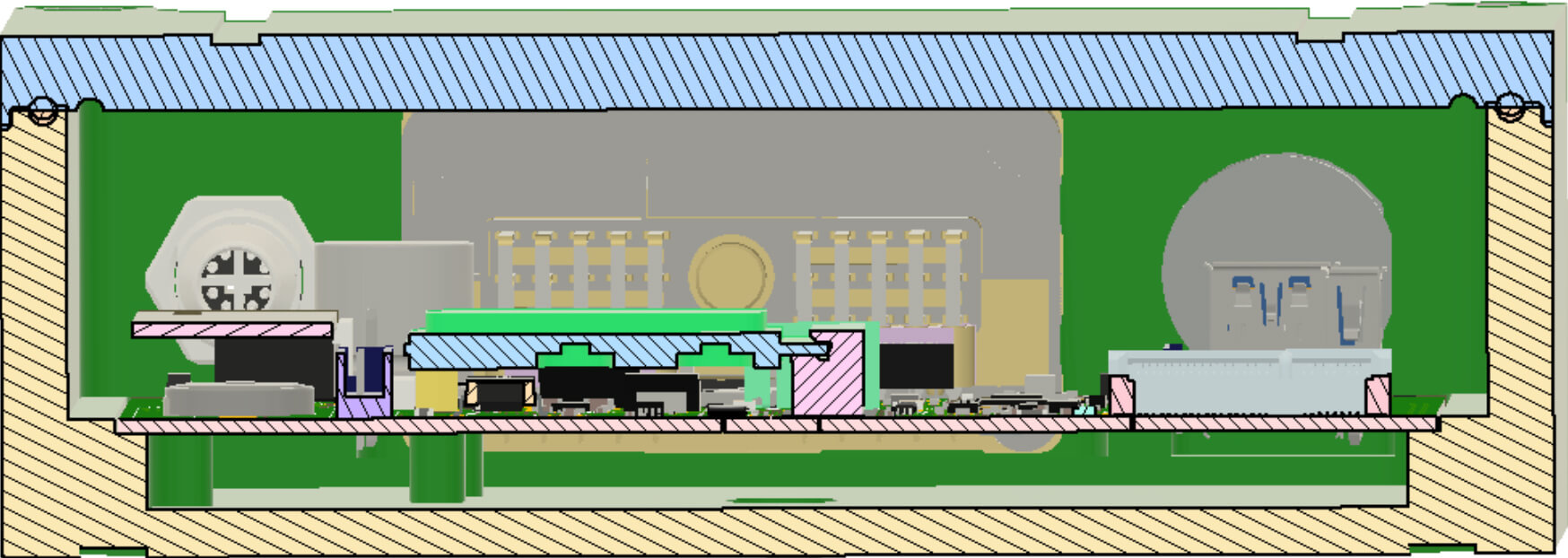

Development of housing system

Harsh operating conditions place high demands on the enclosure systems, our experienced engineering team ensures that your assembly can withstand even the most rugged conditions. In addition to good permanently elastic sealing systems, correct enclosure ventilation is also crucial to achieve sealing classes up to IP69K and to prevent the early failure of your assembly due to large temperature cycles.

PCB integration

With our modern 3D toolchain, we develop circuit components and enclosures simultaneously and can optimally match both. During development, we also simultaneously consider the manageability for efficient production of the assembly.

Qualification and certification

According to your target markets, we have jointly determined the necessary qualification and certification procedures going beyond CE conformity labelling prior to design and implement them according to a mutually agreed timetable.

Components manufacturing

We offer top-quality and efficient manufacturing for assemblies in any quantity and dimension with corresponding quality assurance systems from material reception to final inspection. We design and build the necessary testing equipment in-house in a module-based system.

Delivery of finished components

You determine how the unit is delivered to you, in production-optimised containers or in adapted, service and environmentally friendly cardboard boxes. Labelling, accessories and documentation are compiled according to your specifications.

Service and product maintenance

Even after delivery of your components, we are always available to you with competent service and sustainable updating of the product.